The project at a glance

Home > Project

Our experiment in action

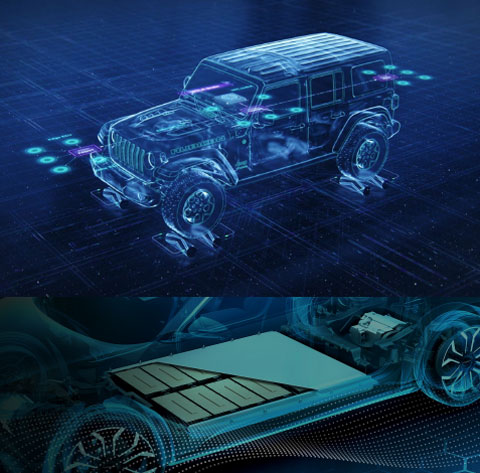

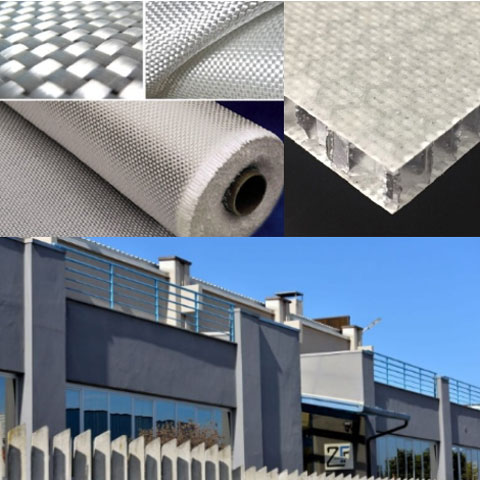

The Tecnoproteo project develops an innovative process for forming thermoplastic composite sheets made with recycled materials, intended for bodywork elements of cars.

The experimentation involves six partners including companies and research centers and holds significant importance for both the Piedmont region and Italy. The project aims to produce medium to large prototypes for the automotive industry and other sectors. It focuses on developing innovative solutions for industrial production that offer environmental and economic advantages.

Within the framework of territorial development policy design, definition, and implementation, the Piedmont Region finances 50% of Tecnoproteo’s activities. The project aligns with the objectives of the SWIch Call for Proposals, supporting business research, development, and innovation activities in line with the Piedmont Regional Programme E.R.D.F. 2021/2027.

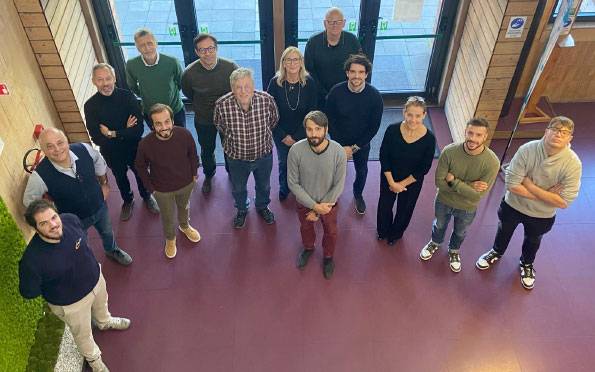

The Tecnoproteo working group. From left to right, front row: Ludovico Focato, Vincenzo Rosati, and Giovanni Marongiu (Eurodies); Andrea Pipino (CRF – Stellantis); Ivan Vazzoler (F.T. Famat); Silvia Avataneo, Stefano Forzano, and Andrea Tassone (CRF – Stellantis).

In the second row, from left: Domenico D’Angelo (Environment Park); Franco Lombardi and Pasquale Russo (Politecnico di Torino); Marina Berrino and Roberto Ramella (Eurodies); Luigi Panza (Politecnico di Torino).

Our big goals

The experimental project studies the characteristics of the new components to evaluate their ability to replace metal ones, preserving the experience and current plants of the partners.

The implementation of the results on an industrial scale will expand the range of achievable products, making them more adaptable to different uses, including multi-sector applications.

During the research phase, the behavior and evolution of prototypes will be monitored to analyze the environmental and economic impact of the component. This analysis will also assess the sustainability of product manufacturing, maintenance, and end-of-life reuse.

The "upcycling" model

Tecnoproteo exemplifies upcycling by enhancing material recovery and transformation. This creative process goes beyond simple recycling, breathing new life and purpose into materials by reinventing their function.