Technological challenges

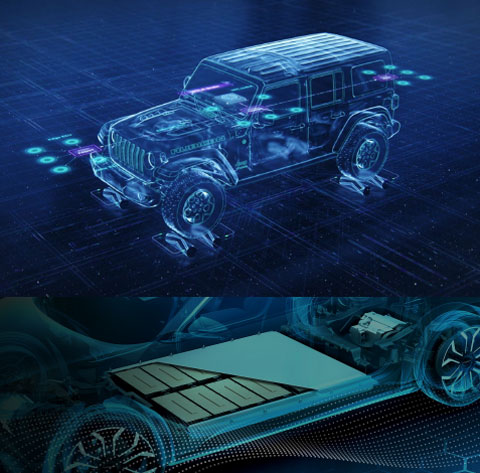

The ongoing evolution in the transport sector directs production chains towards environmental sustainability criteria. Future production strategies are developed with consideration given to the subsequent disassembly and recycling of materials, the transformation of industrial facilities and systems, market dynamics, and legislative directives concerning industrial outlooks. A structured needs analysis identifies weight reduction as a key objective for minimizing consumption, particularly in the context of electric vehicles.

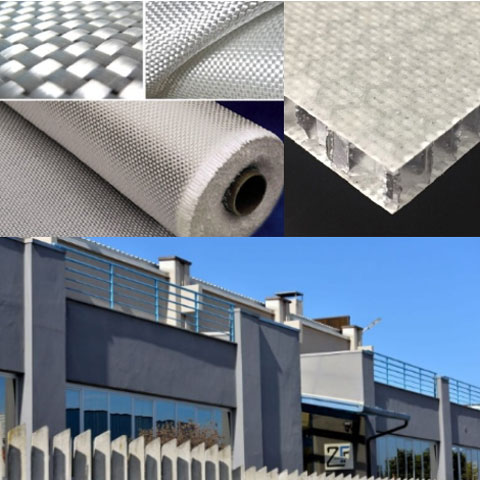

The new thermoplastic composites, created from materials largely from recycling, represent the synthesis between sustainability and lower weight. Furthermore, they constitute an added value to respond to European regulations, which will increasingly require the use of components made of recycled materials for new productions. Thermoplastic materials offer a virtually unlimited lifespan and complete recyclability, surpassing the durability and sustainability of conventional plastic materials, such as thermosetting resins.

The forming process of composite material sheets necessitates a reduced energy expenditure compared to metal sheets. Moreover, the prevailing production methodology for aluminum sheets permits the incorporation of only 30% recycled material, whereas Tecnoproteo strives to employ over 50% of recycled material in the fabrication of composite sheets.

Under the stated conditions, the challenge lies in manufacturing composite sheets at competitive prices while achieving substantial mechanical properties. It must be noted that the attributes of the final product are significantly determined by the integration and interplay between the polymer and the reinforcing fiber.